The construction industry is constantly evolving, and one of the most significant innovations in recent years is the PEB Structure — Pre-Engineered Building Structure. Designed and fabricated in a controlled factory environment and assembled on-site, these structures have transformed how commercial, industrial, and even residential buildings are built. Fast, cost-effective, and sustainable, the PEB Structure is becoming the preferred choice for developers across various sectors.

What is a PEB Structure?

A PEB Structure is a metal building system that is designed and manufactured in a factory and then shipped to the site for quick assembly. These buildings are made using a steel framework and can be customized to meet specific requirements. Unlike conventional buildings, a PEB Structure allows for better precision, reduced construction time, and lower costs due to its efficient use of materials and labor.

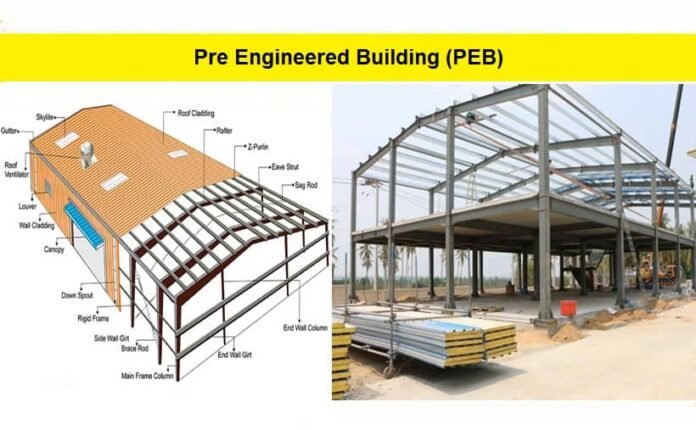

Components of a PEB Structure

Every PEB Structure consists of several key components that work together to create a strong and stable building:

- Primary Frames: These include columns and rafters made from steel plates welded together to form I-sections.

- Secondary Members: These include purlins, girts, and bracing to support the walls and roof.

- Cladding System: The exterior panels (often metal sheets) that cover the roof and walls.

- Accessories: Doors, windows, skylights, ventilation systems, and insulation materials.

Each component in a PEB Structure is designed for optimal performance, contributing to the overall efficiency and strength of the building.

Advantages of PEB Structure

- Cost-Effective

A PEB Structure is usually more economical than traditional construction due to its minimal waste, reduced labor, and faster project completion. - Faster Construction

Since most of the work is done off-site, the on-site assembly is much quicker compared to conventional methods, cutting down the construction timeline significantly. - Customizable Design

A PEB Structure can be tailored to meet specific design, layout, and functional needs, making it ideal for various industries such as warehouses, factories, and sports complexes. - Durability and Strength

Built with high-quality steel, a PEB Structure is designed to withstand extreme weather conditions, seismic activities, and heavy loads. - Eco-Friendly

With minimal waste generation and recyclable materials, PEB Structures are more environmentally friendly than traditional building systems.

Applications of PEB Structure

PEB Structures are widely used across various industries due to their versatility. Common applications include:

- Industrial Buildings: Warehouses, factories, cold storage units

- Commercial Spaces: Shopping malls, showrooms, office complexes

- Agricultural Facilities: Storage barns, processing units, and animal shelters

- Infrastructure Projects: Airport terminals, railway stations, and bus depots

- Sports Facilities: Indoor stadiums, gymnasiums, and training centers

Each PEB Structure can be designed to fulfill the unique requirements of its application, ensuring optimal space utilization and cost efficiency.

Why Choose a PEB Structure Over Conventional Construction?

Opting for a PEB Structure comes with a wide range of benefits that conventional construction cannot easily offer. The precision in design, factory-controlled quality, and adaptability make it a modern solution for today’s fast-paced building demands. Additionally, PEBs offer better scalability, making future expansion easier and more economical.

Another key advantage is reduced maintenance. A Structure made with corrosion-resistant steel and quality coatings ensures long-term durability with minimal upkeep, making it a smart long-term investment.

Challenges and Considerations

While a PEB Structure offers numerous advantages, there are a few challenges that need to be considered:

- Initial Design Planning: Since the entire structure is pre-engineered, accurate and finalized designs are crucial before fabrication begins.

- Transportation: Moving large components from the factory to the site can sometimes be logistically complex.

- Skilled Labor: Proper installation requires trained personnel to ensure that the structure is assembled safely and correctly.

Despite these challenges, the benefits of using a PEB Structure far outweigh the drawbacks, especially when projects are managed by experienced professionals.

Conclusion

A PEB Structure is a game-changer in modern construction, offering unmatched speed, efficiency, and cost savings. As sustainability and innovation continue to drive the future of construction, PEB Structures stand out as a smart solution for developers and business owners alike. Whether you’re building a warehouse, office space, or a sports facility, investing in a PEB Structure can deliver long-lasting value and performance.

With the ability to meet diverse architectural and structural demands, the PEB Structure is more than just a trend—it’s the future of efficient, reliable, and sustainable construction.